Maintaining roads is a perpetual challenge faced by municipalities worldwide. As roads age and wear due to traffic, weather, and other factors, proactive maintenance becomes essential to ensure safety and prolong lifespan. Among the arsenal of road maintenance techniques, micro surfacing stands out as a scientifically backed solution that offers significant benefits in terms of durability, safety, and cost-effectiveness.

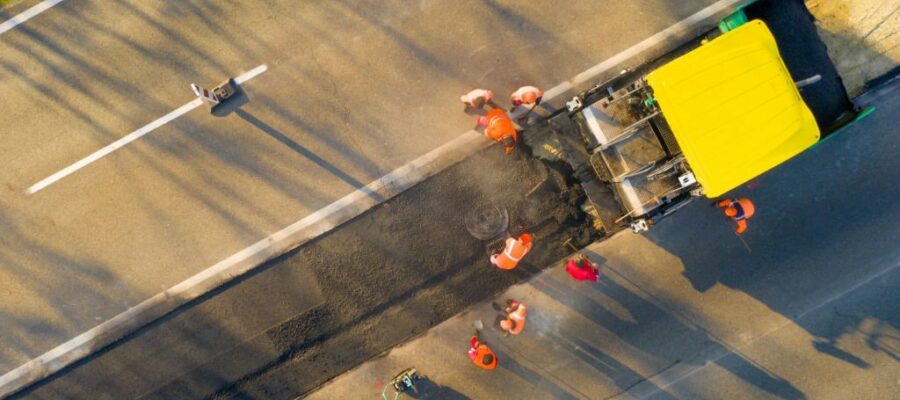

At its core, micro surfacing is a preventive maintenance technique that involves the application of a thin layer of asphalt emulsion mixed with finely crushed aggregate to the surface of a road. This slurry mixture, carefully formulated to meet specific performance requirements, is applied using specialized equipment in a single pass, creating a smooth and durable surface that seals cracks, restores surface texture, and improves skid resistance.

The science behind micro surfacing lies in its carefully engineered composition and application process. The asphalt emulsion used in micro surfacing serves as a binder, holding the aggregate particles together and adhering them to the existing road surface. This binder penetrates into cracks and voids, filling them and preventing water infiltration, which is a leading cause of pavement deterioration.

Moreover, the aggregate used in micro surfacing is selected based on factors such as gradation, shape, and hardness to ensure optimal performance and longevity. Fine aggregates provide smoothness and texture to the surface, while coarse aggregates contribute to durability and skid resistance. By combining different sizes and types of aggregates, engineers can tailor the micro surfacing mixture to meet specific performance requirements for different road conditions and traffic volumes.

The application process is another critical aspect of the science behind micro surfacing. Specialized equipment, including slurry mixing machines and spreader boxes, is used to apply the micro surfacing mixture evenly and uniformly across the road surface. The timing and temperature of the application are carefully controlled to ensure proper curing and bonding of the material, resulting in a durable and long-lasting surface treatment.

The benefits of micro surfacing extend beyond its scientific formulation and application process. One of the primary advantages of micro surfacing is its ability to extend the lifespan of roads significantly. By sealing cracks, restoring surface texture, and protecting the underlying pavement from water infiltration and UV damage, micro surfacing helps prevent further deterioration and delays the need for costly rehabilitation or reconstruction projects.

Additionally, micro surfacing improves road safety by enhancing skid resistance and reducing the risk of accidents, especially in wet or icy conditions. The smooth and uniform surface created by micro surfacing improves vehicle traction and maneuverability, making roads safer for motorists, cyclists, and pedestrians alike. Moreover, the restored surface texture reduces road noise, contributing to a more pleasant and comfortable driving experience.

In conclusion, the science behind micro surfacing is a testament to its effectiveness as a road maintenance technique. By combining carefully engineered materials with precise application processes, micro surfacing offers significant benefits in terms of road lifespan, safety, and cost-effectiveness. As municipalities continue to grapple with aging infrastructure and limited resources, micro surfacing stands out as a valuable tool for preserving and enhancing the integrity of road networks around the world.

- May 27, 2024

- By: admin

- Category:rapid-setting bitumen emulsion, Road patching material

- no comments

- Tags: safety sign boards on road suppliers in mumbaiTraffic sign boards in Mumbai

Related Posts