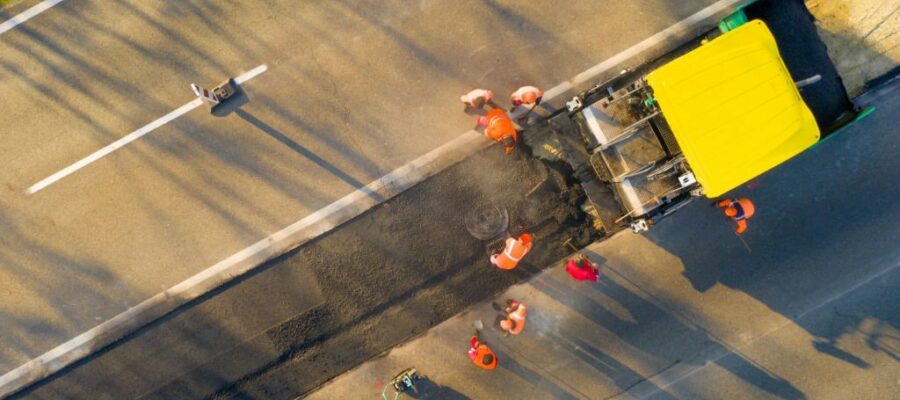

Bitumen emulsion is a versatile material used in various industries, including road construction, waterproofing, and industrial applications. Understanding the science behind bitumen emulsion manufacturing is crucial to appreciate the complexity and precision involved in producing this essential product. In this comprehensive blog, we will explore the intricate process, the role of emulsifiers, and the technology utilized in manufacturing high-quality bitumen emulsions.

What is Bitumen Emulsion?

Bitumen emulsion is a dispersion of small bitumen droplets in water, stabilized by emulsifiers. It is created by breaking down bitumen into tiny particles and dispersing them in water using specialized equipment. The resulting emulsion has distinct properties, making it suitable for a wide range of applications.

Emulsion Manufacturing Process:

a. Dispersion: Bitumen is heated to a precise temperature and then mixed with water containing emulsifiers. The mixture is subjected to mechanical shear forces, such as high-speed agitation or colloid mill, to break down the bitumen into small droplets and disperse them evenly throughout the water phase.

b. Stabilization: Emulsifiers play a critical role in stabilizing the bitumen droplets in the water. These emulsifiers have surfactant properties that reduce the surface tension between water and bitumen, preventing coalescence or re-agglomeration of the droplets.

c. Classification: Bitumen emulsions are classified based on their particle size distribution, which determines their application. The most common classifications are cationic, anionic, and non-ionic emulsions, each with specific characteristics suitable for different purposes.

d. Testing and Quality Control: Throughout the manufacturing process, rigorous testing is conducted to ensure the quality and stability of the bitumen emulsion. Parameters such as particle size, viscosity, storage stability, and breaking characteristics are monitored to meet industry standards and customer requirements.

Role of Emulsifiers:

Emulsifiers are vital components in bitumen emulsion manufacturing. They facilitate the formation and stabilization of bitumen droplets in water. Emulsifiers consist of molecules with hydrophilic (water-loving) and hydrophobic (bitumen-loving) regions. The hydrophilic part attaches to the water molecules, while the hydrophobic part attaches to the bitumen droplets, preventing their coalescence and maintaining their dispersion in the emulsion.

Different emulsifiers are used based on the desired emulsion type and application. Common emulsifiers include surfactants, soaps, and specialized chemicals designed to enhance stability, storage life, and performance characteristics of the bitumen emulsion.

Technology in Bitumen Emulsion Manufacturing:

a. Colloid Mills: Colloid mills are widely used in bitumen emulsion manufacturing. These mills consist of a high-speed rotor and a stationary stator, creating intense shear forces that break down the bitumen into small droplets. The size of the droplets can be controlled by adjusting the mill’s settings, allowing for the production of emulsions with specific particle size distributions.

b. In-Line Homogenizers: In-line homogenizers are another technology used in emulsion manufacturing. They operate on similar principles to colloid mills but offer continuous production capabilities. Bitumen and water, along with emulsifiers, are fed into the homogenizer, where they are subjected to intense shear forces, resulting in a fine dispersion of bitumen droplets in water.

c. Polymer Modification: In some cases, polymer modification is incorporated into the bitumen emulsion manufacturing process. Polymers, such as styrene-butadiene rubber (SBR) or ethylene-vinyl acetate (EVA), are added to enhance the emulsion’s performance and properties. Polymer-modified bitumen emulsions offer improved elasticity, durability, and resistance to cracking, making them suitable for demanding applications.

- June 15, 2023

- By: admin

- Category:Bitumen Emulsion, rapid-setting bitumen emulsion

- no comments

Related Posts

- October 17, 2023

- By: admin

- in: Bitumen Emulsion, Road patching material, Road Repair Solution